Cold-Programmed Shape-Morphing Structures Based on Grayscale Digital Light Processing 4D Printing

November 2, 2023

By Chloe Arrington

Shape-morphing structures that can adapt to various tasks are highly desirable for intelligent machines in numerous interdisciplinary fields. Shape memory polymers are among the most widely used stimuli-responsive materials, especially in 3D/4D printing, for creating shape-morphing structures.

Typically, they undergo a hot-programming step, which involves heating the entire structure, deforming it, and then cooling it down to achieve shape-morphing capability. However, this process offers limited flexibility for reconfiguration.

The limitations imposed by this hot-programming step led researchers to ask, can shape-morphing structures be directly programmed at room temperature to enhance design and programming flexibility? “The answer is yes,” said Jerry Qi, professor in the George W. Woodruff School of Mechanical Engineering.

In March of 2023 a study published by a team of researchers at the Georgia Institute of Technology, led by Qi, developed grayscale digital light processing (g-DLP) 3D printing technology that enabled precise control of the mechanical properties of printed materials, allowing the possibility of cold programming.

Now, after building on this research and the multi-material printing platform and principles of structural mechanics, the research team created shape-morphing structures that can be cold-programmed at room temperature without the need for heating.

This breakthrough was recently published in Nature Communications and was led by Qi in collaboration with researchers from Toyota Motor North America (TMNA) and Toyota Central R&D Laboratories.

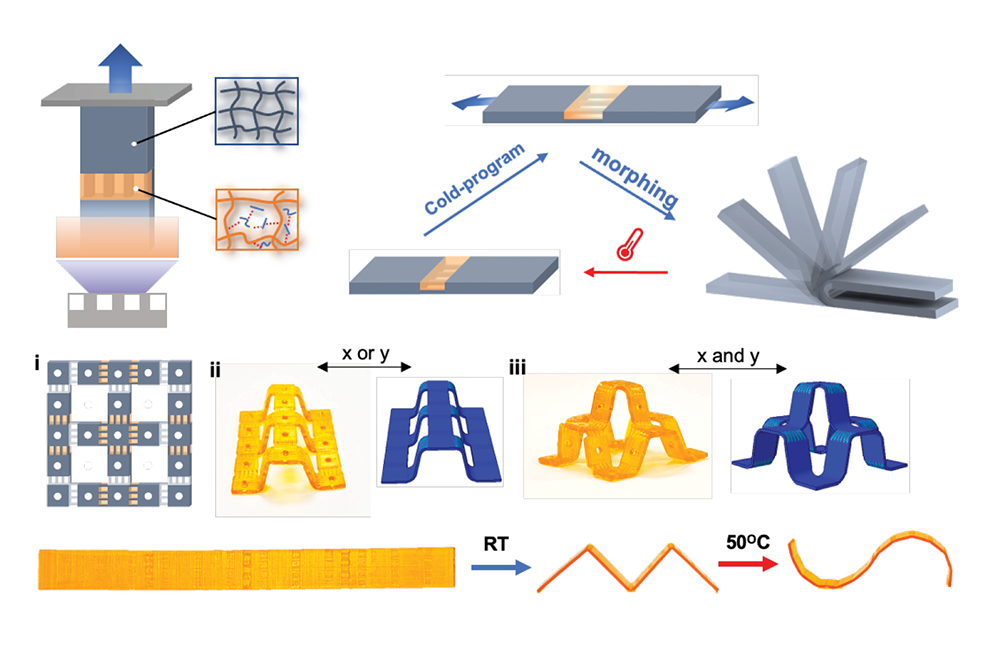

According to Qi, the process of cold programming reshapes a structure at room temperature without heating, providing simplicity and greater versatility for shape morphing. With the multi-material printing capabilities of g-DLP, the team developed a heterogeneous active composite hinge structure that can be cold-programmed by simply stretching it at room temperature.

“This hinge consists of ductile glassy fibers embedded in an organogel-based rubbery matrix and can be easily customized to adapt to different structures and size scales,” said Liang Yue, who is the first author and a postdoc in Qi’s group. Upon stretching, the mismatched recovery of plastic and elastic deformation in these two components results in the bending of the hinge. A constitutive mechanics model was established to describe this morphing behavior and provided a general design framework for complex shape-morphing structures with modular-designed hinges.

Building upon this, complex cold-programmable shape-morphing structures can be designed and manufactured by varying the distribution and orientation of serially connected hinge units. Cold programming enables instant and interactive shape-morphing, while the modular hinge design allows for locally controllable deformation.

By altering the glass transition temperatures of the constituent parts, hinge structures with different thermal responsiveness were developed, offering additional design possibilities.

Qi concluded that the cold programming shape-morphing strategy achieved with the g-DLP printing platform holds broad applicability for 4D printing. “It has potential applications to create new reconfigurable structures with complex shape change for morphing antenna, active metamaterials, origami engineering, and biomedical devices,” said Qi. It represents a significant advancement in the design and fabrication of morphing structures.

About the Research

The work was led by H. Jerry Qi collaborating with Liang Yue, Xiaohao Sun, Luxia Yu, Mingzhe Li, and S. Macrae Montgomery from Georgia Tech, as well as Dr. Yuyang Song and Dr. Masato Tanaka from Toyota Motor North America (TMNA) and Dr. Tsuyoshi Nomura from Toyota Central R&D Laboratories. This research is partially supported by an AFOSR grant (FA9550-20-1-0306).