Education

- National Polytechnic Institute, Mexico, B.S. in Aeronautics, 2001

- National Polytechnic Institute, Mexico, M.S. in Metallurgy, 2003

- RWTH-Aachen University, Germany, Ph.D. in Materials Science, 2008

Background

Luis A. Barrales-Mora, a native of Mexico City is currently an adjunct associate professor at the Georgia Institute of Technology campus Lorraine. He received with distinction a Bachelor of Engineering in Aeronautics in 2001 and a Master of Science in Metallurgy in 2003 from the National Polytechnic Institute, Mexico. In 2003, he was awarded with a grant for doctoral studies from the German Academic Exchange Service. In 2008, he received his Ph.D. (magna cum laude) in Materials Science from the RWTH-Aachen University. He held a postdoctoral position at the Institute of Physical Metallurgy and Metal Physics until 2010, when he was promoted to lecturer and research group leader and from 2015-2016 he was appointed as the interim director of the institute.

Research

Dr. Barrales’ research interests include, among others, the simulation of physical processes of microstructure evolution in metals, and the thermal stability of nanocrystalline materials with an emphasis on the properties of solid-solid interphases and their effect on the synthesis, processing and operation of metallic materials. The next topics have been developed in the past five years:

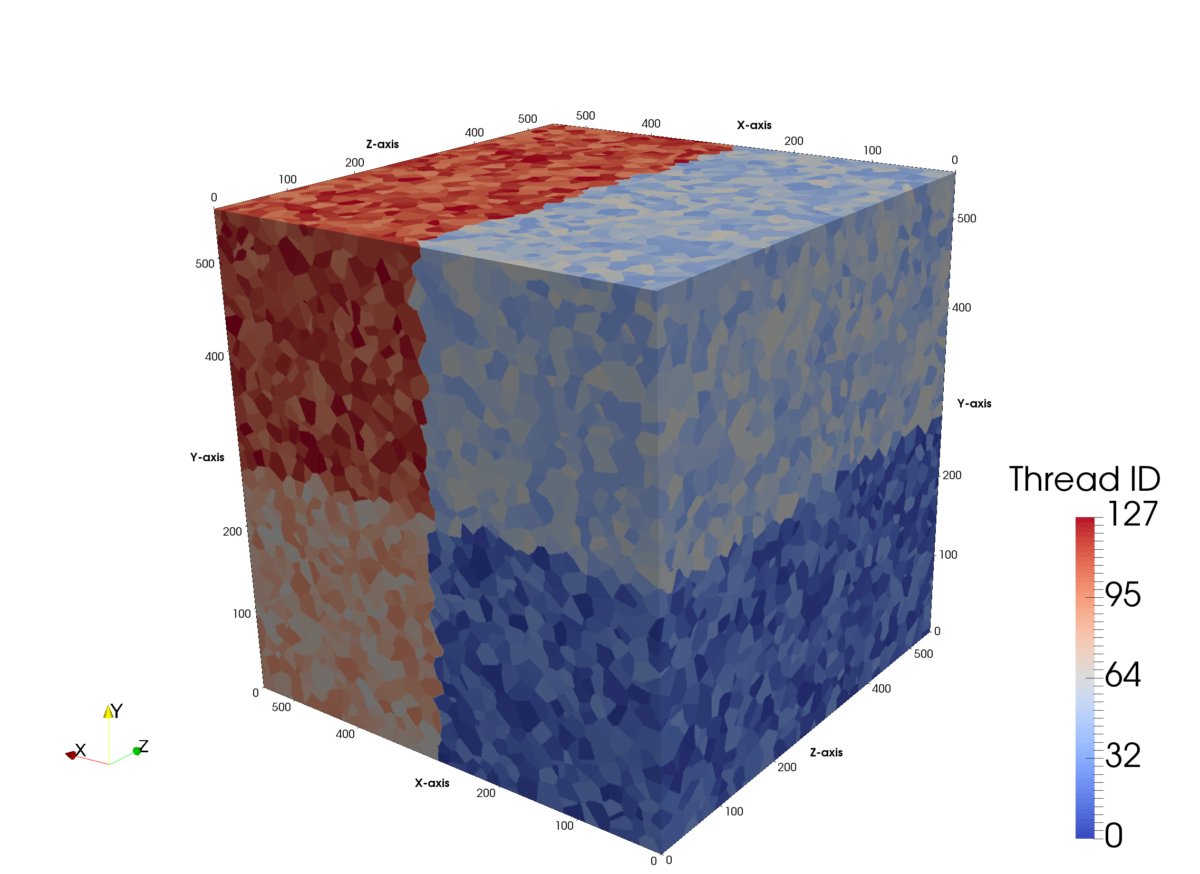

- Massively parallel materials modeling.The activities of my research group involve the development of new simulation approaches for microstructure evolution that make optimal use of massively parallel computer architectures.

- Mechanisms of grain boundary migration.By means of atomistic simulations, we study the mechanisms of grain boundary migration under the effect of different driving forces. The understanding of these mechanisms allows for a better modelling of the phenomena of microstructure modification at the mesoscopic scale.

- Heat treatment in high-Mn steels and high entropy alloys. The changes of microstructure and texture during heat treatment are studied experimentally and by means of computer simulations.

- Low-loss electrical steel for electromobility. New electrical steels with reduced magnetic losses are developed for their application in electrical cars.

Figure 1. Optimized microstructure for a parallel computer architecture. To minimize remote memory access, the grains were clustered topologically and assigned to specific computational nodes. This allowed a speed up of 20x compared to similar parallel simulations for a simulation of grain growth.

Distinctions and Awards

- Research Grant, Outstanding Young Scientists Program of the German Research Foundation (DFG), 2008

- Outstanding Young Scientist Award, 3rd Conference on Recrystallization and Grain Growth, Korea, 2007

- Grant Award for Doctoral Studies, German Academic Exchange Service (DAAD), 2004

- Honorable Mention for Outstanding Academic Achievements, Mexico, 2001