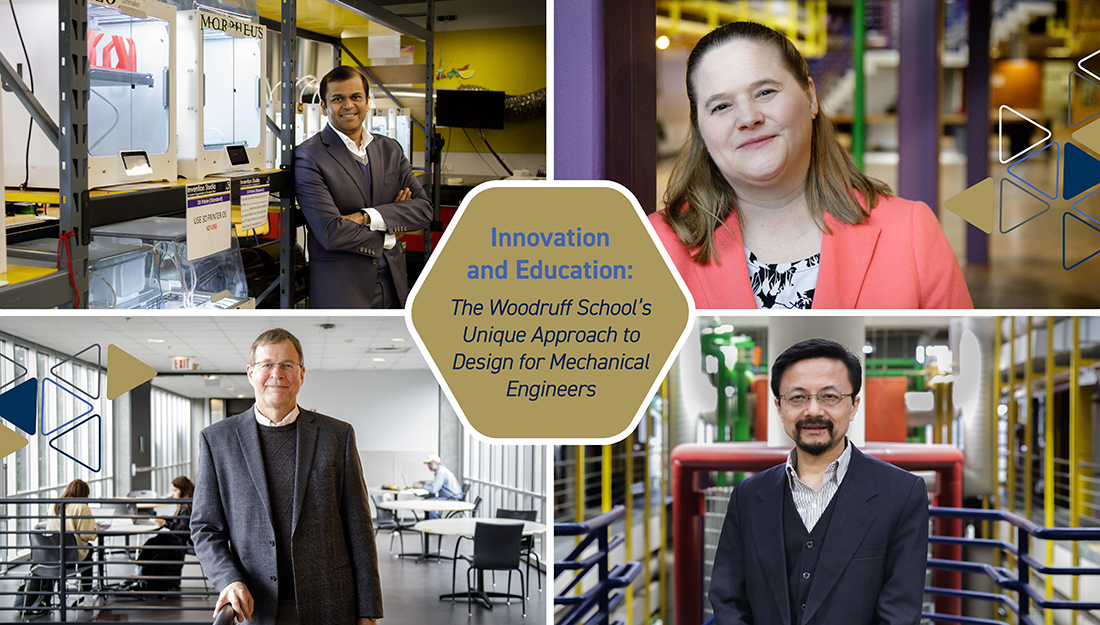

Pictured left to right, top to bottom: Director of Design and Innovation Amit Jariwala, Professor Julie Linsey, Associate Chair for Administration Bert Bras, and Professor Yan Wang.

Innovation and Education: The Woodruff School's Unique Approach to Design for Mechanical Engineers

January 29, 2024

By Ian Sargent

Mechanical engineering, in the broadest sense of the discipline, touches a vast array of processes and systems, encompassing familiar industries and niche startups. Rapid technology advances mean engineering skills and methods change frequently to adapt to newer materials, tools, or customer needs. At its core, however, the intersection of design and innovation drives engineering, shaping the future of products and manufacturing processes. At the forefront of this intersection is the George W. Woodruff School of Mechanical Engineering at Georgia Tech, well known for its commitment to design education and unique approach to understanding the crucial role design plays in educating future engineers.

Design Education: Bridging the Gap Between Art and Engineering

Amit Jariwala is the Director of Design and Innovation at the Woodruff School and is responsible for developing industry partnerships to support the innovative learning experience at the school. Through these connections Jariwala can also keep a close study on the skills and experience companies are looking for in prospective hires, which can help identify areas of focus across the school’s curriculum.

Amit Jariwala is the Director of Design and Innovation at the Woodruff School and is responsible for developing industry partnerships to support the innovative learning experience at the school. Through these connections Jariwala can also keep a close study on the skills and experience companies are looking for in prospective hires, which can help identify areas of focus across the school’s curriculum.

Jariwala has been in his current position since 2012 and has played a key role in helping expand the design curriculum facilities at the Woodruff School, which include the IDEA Lab, the Flowers Invention Studio, and the Montgomery Machining Mall. These facilities, collectively known as the Wepfer Design Commons, have seen rapid growth and an enhanced focus on supporting students with their design pursuits in and out of the classroom.

This hands-on approach isn’t a replacement for the technical and mathematical rigor necessary to engineering projects but is a re-emphasis of creating solutions with the end-user in mind. "I do not see design and engineering as opposing ends; rather, I consider design as a tool that leverages engineering to solve a problem," Jariwala said, underscoring the essence of the Design Sequence at the Woodruff School, where courses offer practical tools to merge artistic and technical considerations seamlessly.

The Design Sequence, according to Jariwala, addresses the critical need for end-user desirability, often overlooked in traditional engineering. Through collaborations with industry experts and real-world insights shared in classrooms, the Woodruff School ensures students develop a holistic perspective.

"Too often, as engineers, we tend to focus too much on technical feasibility but underestimate the value of end-user desirability,” Jariwala said. “We will need a lot of human-centric, empathetic engineers and designers who can work together to improve the human condition, and I believe that graduates from the Woodruff School of Mechanical Engineering will have a pivotal leadership role to play in creating these solutions.”

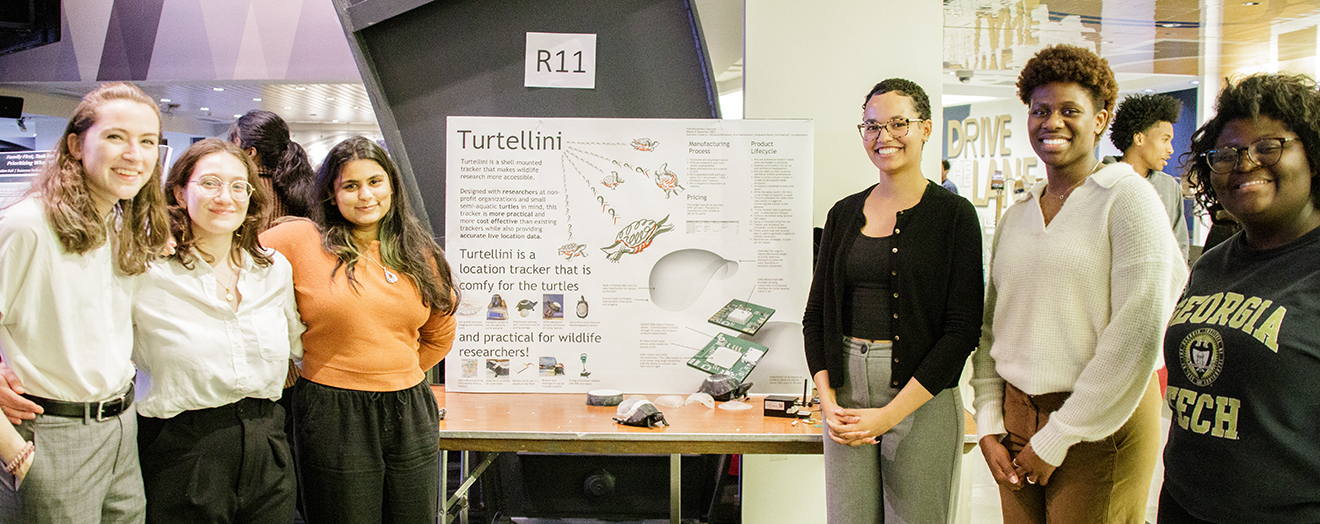

Interdisciplinary Capstone Design team Turtellini including students Eva Noertoft (ME); Ireoluwa Adaramola (ME); Gabrielle Calderon (ECE); Kruti Maheshwari (ID); Veronica Pantalone (ECE); and Stephanie Rawls (ME). Capstone Design is a culminating course offered to undergraduate students in several disciplines at Georgia Tech. Students work in teams to design, build, and test prototypes with real world applications. At the end of each semester students showcase their efforts at the Capstone Design Expo.

Design Cognition: Unraveling the Engineering Mind

Julie Linsey, professor and director of the Innovation, Design Reasoning, Engineering Education, and Methods (IDREEM) Lab at Georgia Tech, spends a lot of time thinking about how people think, especially when they’re thinking about design.

Julie Linsey, professor and director of the Innovation, Design Reasoning, Engineering Education, and Methods (IDREEM) Lab at Georgia Tech, spends a lot of time thinking about how people think, especially when they’re thinking about design.

Linsey’s area of research is design cognition, a blend of cognitive psychology and engineering design research. Her work puts under a lens the cognitive processes behind design choices with the goal of creating better tools and approaches to enhance innovation, delving into the intricacies of how engineers navigate the design process, particularly in the fuzzy front end of design, where prototyping decisions are pivotal.

"In the early design process, there's a lot of human cognition that comes into play," says Linsey, whose interdisciplinary approach draws from psychology, sociology, and ethnography. Biases such as the halo effect and primacy and recency biases can lead to systematic mistakes.

Primacy bias, for example, refers to the tendency to give more weight or importance to the first pieces of information encountered during the design process. This bias can influence decision-making and design choices based on the early information received, potentially overlooking alternative solutions or aspects introduced later in the process.

Imagine a design scenario where engineers receive initial specifications emphasizing a particular material or manufacturing method. They might develop a bias towards that option without fully exploring alternatives. This early emphasis can lead to a design that is suboptimal or misses out on more innovative and efficient solutions that might emerge later in the process.

Linsey's work aims to develop design methods that minimize these biases, fostering a more innovative and creative approach among engineers. Acknowledging the biases can mitigate some, but not all negative effects, so the work done by Linsey and her team in the IDREEM Lab is indispensable to the Woodruff School’s design curriculum.

“I have to understand the cognition of the engineers of the designers and then how their tools, their methods, all relate to producing; much of my work is focused on how we help engineers become more innovative, more creative.”

Linsey's empirical research was among the first to document the multifaceted learning occurring in spaces like the Flowers Invention Studio. While anecdotally it was clear that there would be benefits to makerspaces, there’s now the data to underpin these claims.

"They're building their prototyping skills," Linsey said. “They're building their confidence, but we also see a lot of other things. They're building their interpersonal skills, their self-awareness.”

Linsey’s work has shown that makerspaces like the Invention Studio not only enhance technical skills but also nurture qualities essential for engineers tackling the open-ended challenges of the future, while developing effective communication and leadership skills.

Multi-Scale Computational Design: Shaping the Digital Frontier

Spearheading research on the frontier of engineering technology is Yan Wang, director of the Multi-Scale Systems Engineering Research Group and a professor at the Woodruff School.

Spearheading research on the frontier of engineering technology is Yan Wang, director of the Multi-Scale Systems Engineering Research Group and a professor at the Woodruff School.

Wang specializes in multi-scale computational design systems, tools enabling engineers to analyze and model materials, products, or processes at various levels of detail and size—from the macroscopic shape of an airplane’s wing to its microscopic material structure—all in one computational system.

“Engineering design is an iterative process,” Wang says. “Instead of iteratively building physical prototypes to test and evaluate designs, building digital models or virtual prototypes to evaluate their performance in a computer can significantly reduce the cost and time associated with the design iterations.”

Wang envisions a future where engineering seamlessly integrates product design and materials design. His research group tackles the challenges posed by integrating the complex math of both the macro and micro scales, seeking innovative computational approaches to overcome them.

"Computational tools that can model and evaluate systems at multiple length scales are crucial to accelerate product innovation," said Wang.

The technical challenges lie in predicting the properties of materials and the performance of products. The ‘curse-of-dimensionality challenge,’ where computational costs grow exponentially with the number of variables, necessitates the novel approaches that Wang and his team take, including developing algorithms designed for quantum computers.

Wang also sees the recent explosion in AI tools amplifying the speed at which engineers can explore design solutions.

“As an alternative to traditional physics-based models, which are often computationally expensive, machine learning models can be used to predict the property and performance very efficiently,” he said. “Nevertheless, I do not believe AI tools can completely replace human designers, because these tools can only do jobs very similar to what they have been trained with. To perform non-repetitive tasks, physical knowledge accumulated by human beings is still irreplaceable, which is our intuition and wisdom.”

Wang’s research highlights the forward-thinking approach the Woodruff School is taking to design, pushing the boundary through advanced research, and better preparing students to be the engineers of tomorrow.

Sustainable Design: Engineering for a Better Tomorrow

Likewise, sustainability remains critical to the engineering of tomorrow, and Bert Bras, Associate Chair for Administration, has long been a champion of sustainable design. Bras, who also holds the Brook Byers Professorship in Energy and Environmental Systems, had his interest sparked in 1992 when discussions about product take-back laws in Europe were gaining traction. He saw an opportunity to research making products easier to dispose of, which led him to his first NSF grant titled “Enhancing Reusability by Design.”

Likewise, sustainability remains critical to the engineering of tomorrow, and Bert Bras, Associate Chair for Administration, has long been a champion of sustainable design. Bras, who also holds the Brook Byers Professorship in Energy and Environmental Systems, had his interest sparked in 1992 when discussions about product take-back laws in Europe were gaining traction. He saw an opportunity to research making products easier to dispose of, which led him to his first NSF grant titled “Enhancing Reusability by Design.”

“I realized it was a completely new area that gave me and students a good feeling to work in,” he said. “After 31 years, I still find the whole area of sustainable design very rewarding and exciting. It is nice to know that you work in an area that is actually good for the planet.”

His passion for sustainable design now extends beyond remanufacturing, encompassing the entire life cycle and drawing inspiration from natural ecosystems. Bras sees the future of sustainable design evolving at multiple levels, with principles integrated into standard engineering practices. "To get to true sustainable development, we need to design new energy systems, new mobility systems, more advanced buildings, and building energy systems," he said.

Under Bras' guidance, the Sustainability Design and Manufacturing Lab at Georgia Tech plays a pivotal role in helping companies evaluate their economic and environmental impact. By developing models that quantify the impact of sustainability-related options, the lab aids companies in making informed decisions. Bras recounts successful projects, such as reducing volatile organic compound emissions in collaboration with Ford, demonstrating that sustainable design can lead to both environmental and financial win-win situations.

Bras shares his passion and enthusiasm for sustainability with students and seizes on their desire to have a positive impact on the world.

“Most already realize that we need to reduce our greenhouse gas emissions and that engineering can help with that,” he says. “What many don’t realize is that a lot starts with good engineering, that is, reducing waste and increasing efficiency, which includes making sure that you don’t overdesign products.”

Bras also urges his students to think beyond the realm of engineering when it comes to solving problems in sustainability, encouraging them to consider human behavior and economic factors.

“Taking a systems perspective and looking at the bigger picture is very important for students to learn," he said. “That’s when you can differentiate in true advancements and worthwhile trends, versus hype.”

Forging Future Leaders in Design and Engineering

The Woodruff School continues to position itself on the vanguard of innovation, where design is not just a tool but a guiding principle, directing the approach the school takes to education, research, and technology, and collectively shaping the narrative of design in mechanical engineering.

Looking ahead, new programs and initiatives will provide unique opportunities for transformative research and education. Currently in its early stages, TechMade will be a new interdisciplinary initiative tapping into the technological resources available across Georgia Tech.

"The vision for TechMade comes from the Woodruff School's desire to integrate art, science, and engineering into design thinking," said Devesh Ranjan, Eugene C. Gwaltney, Jr. School Chair.

TechMade is supported by the Woodruff School and led by Professor Carolyn Seepersad, together with Professor Wayne Li from the School of Industrial Design. The initiative focuses on creating design threads that complement analytical and computational skills with design thinking and hands-on fabrication opportunities in each year of the mechanical engineering undergraduate curriculum. At the graduate level, the initiative will nurture a cadre of TechMade fellows who integrate engineering design into other technical areas to address complex multidisciplinary challenges.

The Woodruff School's commitment to design education, cognitive research, multi-scale computational design, and sustainable design propels its graduates into the workforce as empathetic problem-solvers and leaders. As Jariwala aptly puts it: "We are preparing next-generation leaders who are empathetic problem-solvers armed with the ability to learn, collaborate, adapt, and create solutions to improve the human condition.”